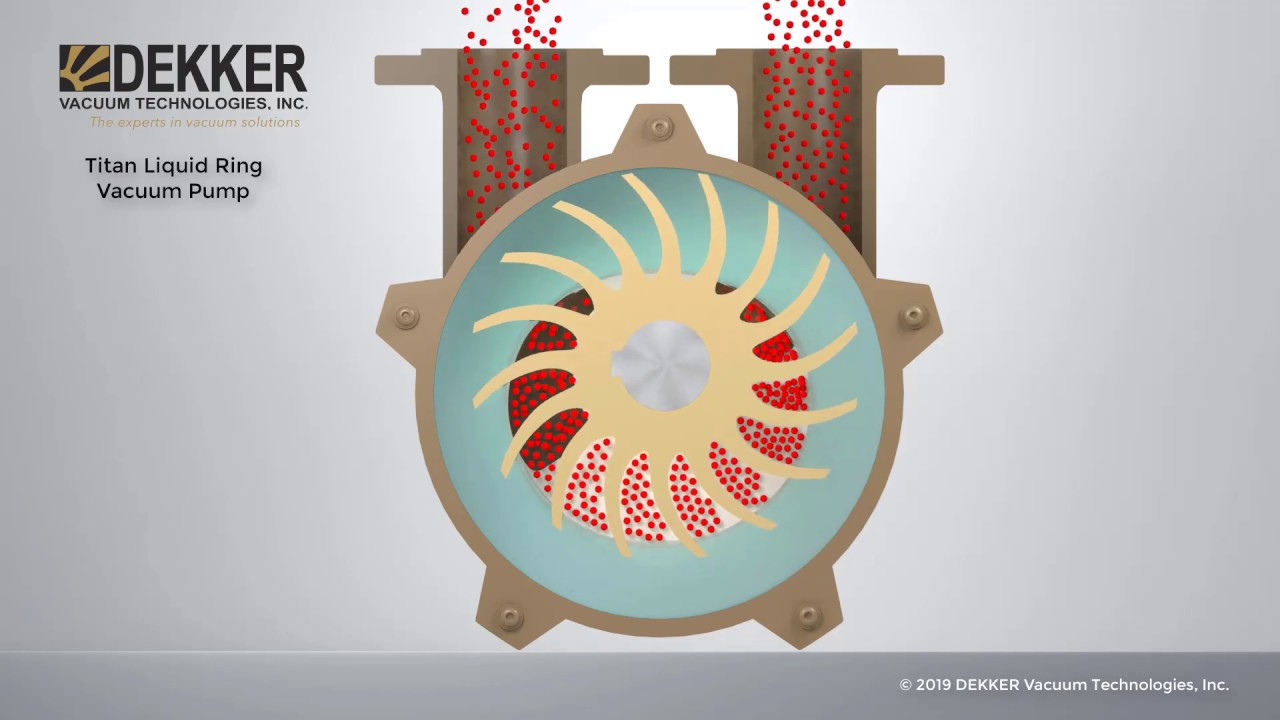

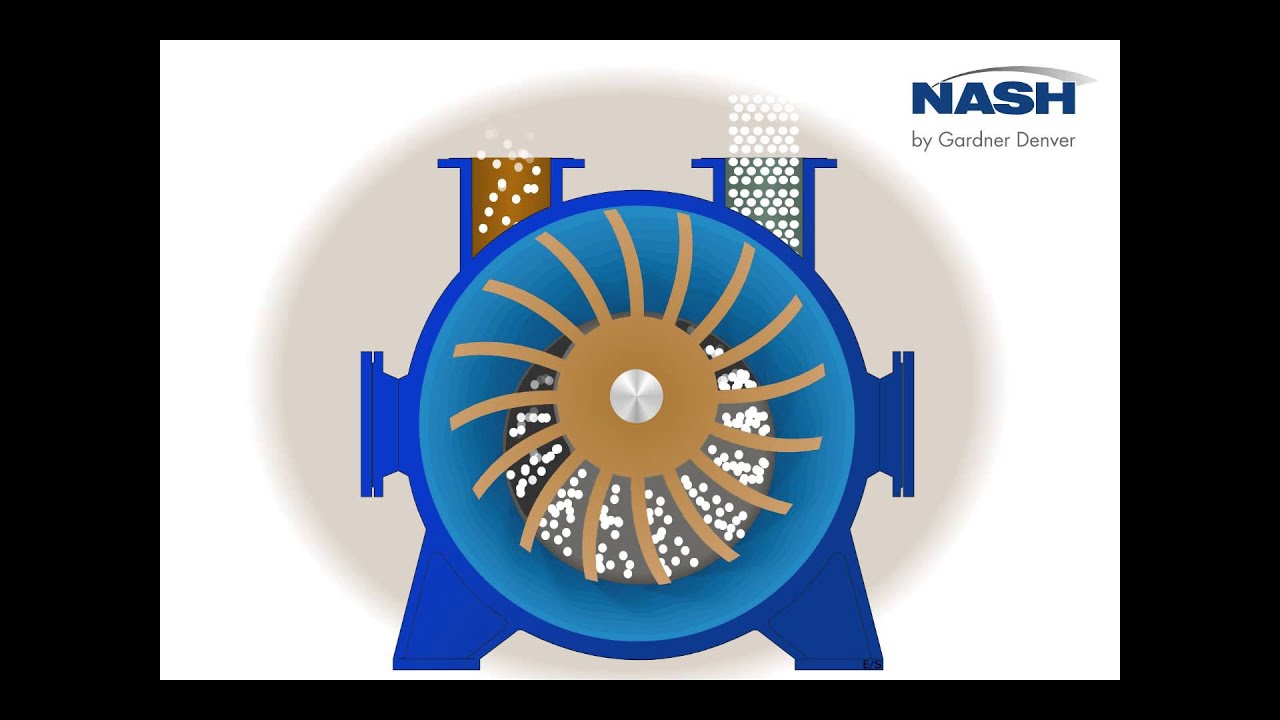

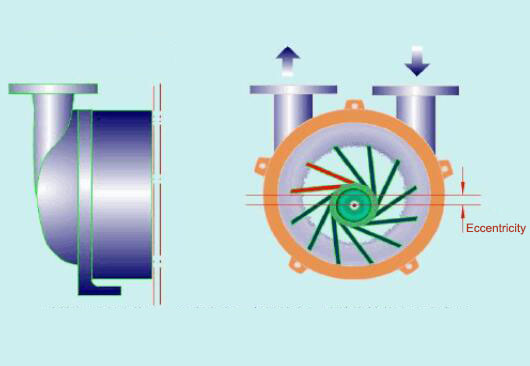

To produce vacuum in a two stage liquid ring vacuum pump a multi blade impeller on a shaft is positioned eccentrically in a cylindrical housing that is partially filled with sealing liquid as the shaft turns a liquid ring is created by the centrifugal force generated by the rotating impeller.

Liquid ring vacuum pump working principle pdf.

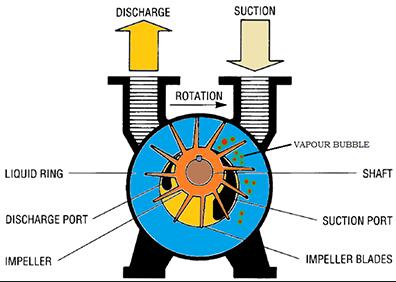

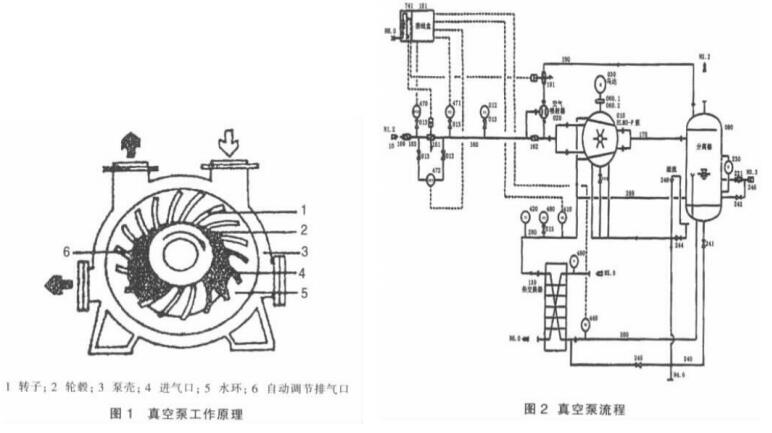

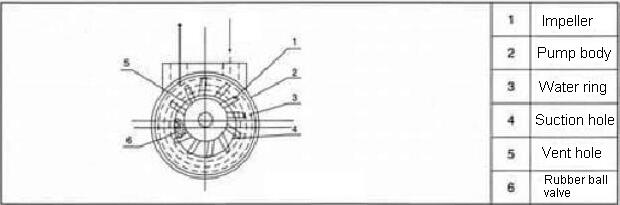

As shown in the diagram of the working principle of the liquid ring pump the liquid ring pump is.

As the rotor spins the seal liquid inside the pump forms a rotating liquid ring on the inner surface of the body forming the liquid ring.

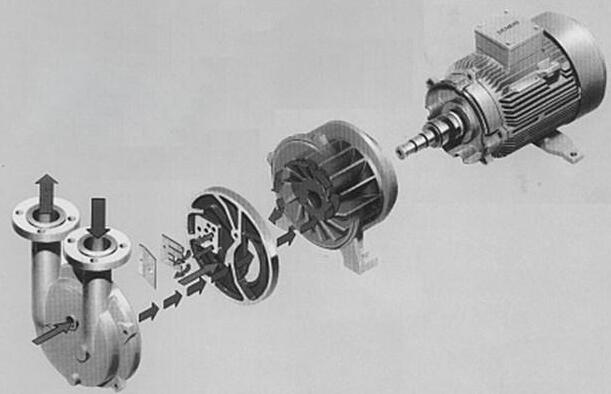

Above figure shows construction exploded view of a typical flat plate type vacuum pump.

Our liquid ring vacuum pump design was the first of its kind at the turn of the 20th century and has.

Liquid ring vacuum pump also called liquid ring vacuum pump for short is a kind of coarse vacuum pump which can obtain pressure.

Pump designed to remove gases through the use of rotating impeller blades that enter and leave a ring of liquid.

Its pressure range is 1 2 x105pa gauge pressure under specific conditions.

The klrc is a non pulsating vacuum.

Liquid ring vacuum pumps are rotating positive displacement machines providing process vacuum in industrial applications such as chemical electrical power environmental food beverage processing and packaging marine mining oil gas pharmaceutical pulp paper and textiles.

The working principle of a liquid ring pump is based around a pump body and an eccentric rotor.

Liquid ring pump can also be used as compressor it belongs to low pressure compressor.

They are typically used as a vacuum pump but can also be used as a gas compressor the function of a liquid ring pump is similar to a rotary vane pump with the difference being that the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression chamber seal.

Liquid ring pump is widely applied in many industry fields due to the advantages of isothermal compression process simple structure and liquid sealing.

The impeller forces this sealing liquid to the periphery of the pump casing where it forms a moving ring of liquid around a.

Based on the actual operating cycle of suction compression discharge expansion a universal theoretical model for performance of liquid ring pump was established in this study to solve the problem that the theoretical models deviated.